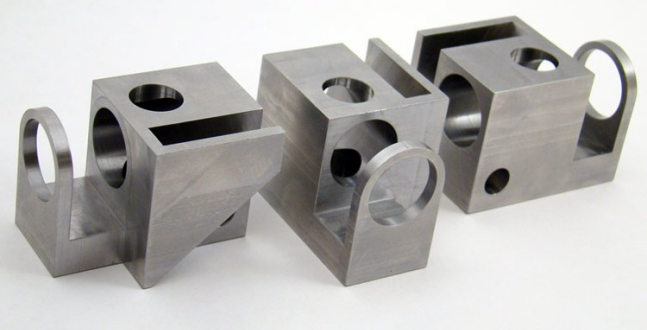

A machine is used in the process of precision CNC milling and turning, which results in smaller and more exact bits. This kind of machining is used in the automotive and aerospace sectors to mold components and eliminate waste. This article discusses how industrialists put this technology to use.

Milling and turning are done with precision using CNC equipment.

Using rotary tools and computer numerical control (CNC) milling and turning, items may be made from material blocks. As it goes around the block, the tool gives it a form. CNC milling and turning are used in various industries, including aerospace, automotive, medical, and the military.

Milling and turning using a CNC machine are quick and accurate. For example, milling and turning using a CNC machine may produce intricate designs that are impossible to create using more conventional methods.

Industriousness

Milling and turning with a CNC give several benefits not available with conventional machining. These gadgets make it possible to create intricate forms and components that are nicely crafted. The following are some examples of where industrial CNC machining may be used.

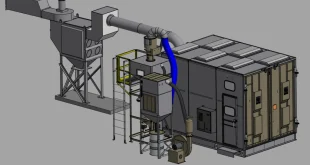

The use of CNC milling allows the production of aircraft components with complex curves and angles, which would otherwise require a significant amount of manual labor using more conventional techniques, much simpler.

It is impossible to achieve the same level of accuracy in implants, prosthetics, and other types of medical equipment without precision machining.

Modern automobiles, with their intricate curves and sharp edges, are made easier to machine using CNC.

The production of furniture is a challenging industry that may gain from the capacity of industrial CNC machining to mass-produce intricate designs in large quantities rapidly.

Conclusion

Milling and turning using computer numerical control are crucial for producing high-quality industrial components. Milling utilizes flat blanks to produce complicated structures while turning employs round or curved blanks to manufacture its products. When the machine is properly configured, it is simple to produce components comparable to those on the market or superior to those on the market AS PRECISION provides experienced services in precision machining and tailors solutions to meet the specific requirements of each customer.