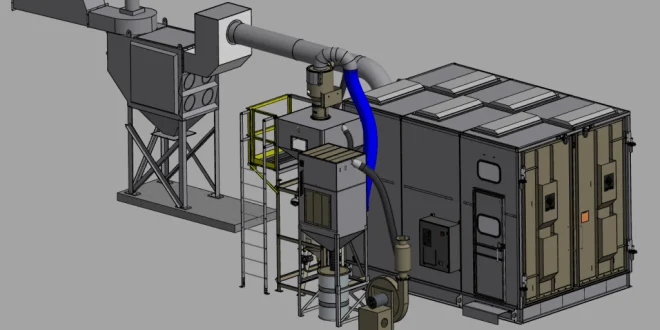

Blast booths are essential for various industrial processes, particularly sandblasting. These enclosed spaces protect both operators and the environment from the abrasive materials used in the blasting process. However, one often underestimated factor in blast booth operations is temperature. In this comprehensive guide, we will delve into the critical aspects of temperature considerations within blast booths, from the impact of ambient temperatures to cooling options for operators. Let’s explore how temperature plays a vital role in ensuring the efficiency and safety of sandblasting booths.

Impact of Ambient Temperatures

The ambient temperature surrounding a sandblasting booth can significantly affect its performance. In colder climates, low temperatures can lead to issues such as delayed material flow, reduced abrasive efficiency, and potential damage to equipment. On the other hand, excessively high temperatures can impact operator comfort and lead to overheating hazards. To optimize the operation of a sandblasting booth, it’s crucial to consider the local climate and take appropriate measures to mitigate temperature-related challenges.

Effects of Heating Elements

In regions with cold winters, the installation of heating elements in the blast booth can be a game-changer. These heating systems maintain a consistent internal temperature, ensuring that the abrasive material flows smoothly and efficiently. Moreover, they enhance operator comfort by preventing extreme cold conditions within the booth. Heating elements are a valuable addition to sandblasting booths, especially in environments where temperatures can plummet.

Monitoring and Controlling Systems

To ensure optimal temperature conditions, monitoring and controlling systems are indispensable. These systems offer real-time data on the internal temperature of the blast booth, allowing operators to make necessary adjustments. Advanced technology can even automate the temperature control process, maintaining a precise and steady environment. Monitoring and control systems are crucial for preventing abrupt temperature fluctuations that could negatively impact the sandblasting process.

Preventing Overheating Hazards

While cold temperatures can pose challenges, overheating hazards are equally concerning. Prolonged exposure to high temperatures within a blast booth can jeopardize operator safety and equipment integrity. To address this issue, it’s essential to implement safety measures such as ventilation systems, temperature alarms, and emergency shut-off procedures. These precautions not only protect operators but also extend the lifespan of the booth itself.

Cooling Options for Operators

Operator comfort is paramount in any industrial setting. When working inside a blast booth, operators can face discomfort due to elevated temperatures. To address this, consider providing cooling options within the booth, such as fans or air conditioning. These amenities not only enhance the working conditions for operators but also contribute to their overall productivity and well-being.

Maintaining Visibility with Temperature Variations

Temperature fluctuations can sometimes lead to condensation on the blast booth’s viewing window, reducing visibility. This can compromise the precision of the sandblasting process and create safety hazards. To maintain clear visibility, explore options like heated viewing windows or anti-condensation treatments. These measures ensure that operators can monitor their work effectively, even in changing temperature conditions.

In conclusion, temperature considerations are integral to the efficient and safe operation of blast booths, especially in sandblasting applications. Whether you are dealing with extreme cold or sweltering heat, understanding the impact of temperature on your equipment and operators is essential. By investing in heating elements, monitoring systems, safety precautions, cooling options, and visibility enhancements, you can optimize your blast booth’s performance and create a safer working environment. Don’t underestimate the importance of temperature control; it can make all the difference in your sandblasting booth operations.