When it comes to circuit board assembly, one crucial aspect that shouldn’t be overlooked is the PCBA test. This article will delve into the significance of PCBA testing in ensuring optimal functionality for circuit boards. We’ll also highlight how Maker-ray, a leading brand in electronics manufacturing, excels in providing reliable PCBA testing solutions.

Understanding PCBA Test

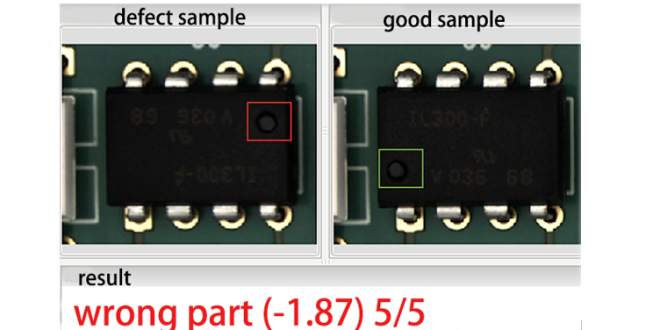

What is PCBA Test? PCBA (Printed Circuit Board Assembly) test refers to a comprehensive evaluation process conducted to verify the functionality and quality of assembled circuit boards. It involves rigorous testing of various parameters, including electrical connectivity, component placement, signal integrity, and more.

Ensuring Reliable Circuit Board Functionality By performing a PCBA test, manufacturers can identify and rectify any potential defects or malfunctions before the circuit boards reach end-users. This preventive measure ensures that the final products meet the highest quality standards and perform optimally in real-world applications.

Key Benefits of PCBA Testing

Enhanced Quality Assurance PCBA testing allows for thorough inspection of the assembly process, enabling manufacturers to catch errors or defects early on. This quality assurance measure minimizes the risk of faulty products reaching the market, safeguarding the reputation of both the brand and the end-users.

Improved Product Performance Testing PCBAs helps ensure that all components are functioning as intended. By validating the circuit board’s performance under different conditions, manufacturers can fine-tune designs and optimize functionality. This ultimately leads to superior product performance and customer satisfaction.

Maker-ray: Your Trusted PCBA Test

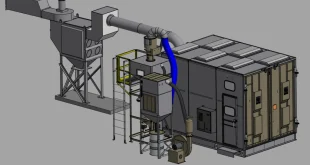

Cutting-Edge Testing Solutions Maker-ray, a reputable brand in electronics manufacturing, specializes in providing advanced PCBA testing solutions. Their state-of-the-art equipment and experienced technicians ensure thorough and accurate testing to meet the highest industry standards.

Quality-Centric Approach With a strong emphasis on quality, Maker-ray prioritizes customer satisfaction by delivering flawless circuit board assemblies. Their rigorous PCBA testing procedures guarantee that each product leaving their facility is reliable, durable, and performs optimally under diverse operating conditions.

Conclusion

In conclusion, PCBA testing plays a pivotal role in ensuring the functionality and reliability of circuit boards. By partnering with a trusted brand like Maker-ray, you can leverage cutting-edge testing methodologies to deliver high-quality products to your customers. Embracing PCBA testing as an integral part of the manufacturing process will not only enhance your brand’s reputation but also improve customer satisfaction and drive long-term success.